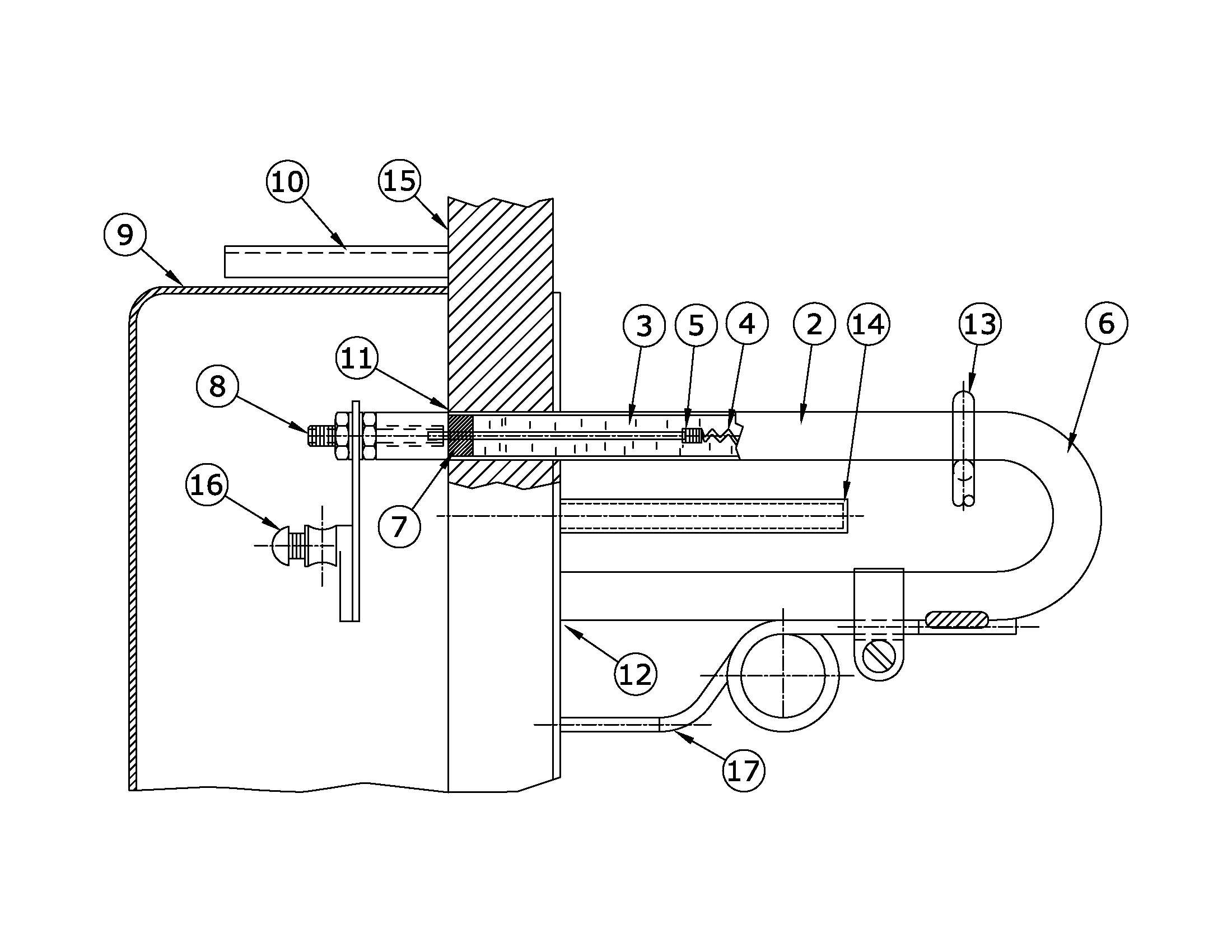

8″ & 10″ – 150# Flanged Immersion Heaters

Flange immersion heaters are designed for use in tanks and pressurized vessels to heat both gases and liquids. A flanged immersion heater will typically mate with a companion flange that is either welded to a tank or in the case of circulation heaters, to a pipe body. AccuTherm flange heaters are designed to provide our customers with a long-lived, dependable, trouble-free heater for their application requirements. A properly designed flange heater will provide a high degree of efficiency as the energy that is generated is quickly dissipated directly into the medium that is being heated.

- Element bends repressed uniformly to insure electrical insulation integrity.

- One piece forging of hex, thread and riser assures reliability.

- Element spacers prevent hot spots.

- Bussing is permanent and encapsulated in epoxy seal.

- UL CSA label furnished on all standard copper, stainless steel and Incoloy sheathed heaters, NEMA Type 1, 4 and 4x environments.

|

Flange Size

|

C

|

D. Max

|

E

|

F

|

G

|

H

|

J

|

K

|

|

8″ – 150#

|

5

|

7 ½

|

9 ¾

|

13 ½

|

11 ¾

|

8

|

⅞

|

1 5⁄16

|

|

10″ – 150#

|

5

|

9 ½

|

9 ¾

|

16

|

14 ¼

|

12

|

1

|

1 ¾

|

Standard Features

Tubular Elements are welded or silver soldered into a hex head pipe thread fitting. Elements have 80/20 nickel-chromium resistance coils centered in a heavy gauge metal tube surrounded by magnesium oxide insulation. Through rolling, the magnesium oxide is compacted for rapid heat transfer from the coil to the sheath. Elements are annealed, bent and then 360° repressed to insure magnesium oxide integrity in the bent area. .312″ diameter elements for operation up to 277 volts.

Screw Plug Fittings of forged brass, silver soldered to the sheath, are furnished as standard with copper sheathed heaters. Steel and stainless steel sheathed elements are welded into fittings of like material.

Outlet Boxes are furnished on heaters without a built-in thermostat. A 4″ NEMA 1 octagon outlet box having 3/4″ knockouts is standard.

2″ NPT stock heaters (without thermostats) are furnished with cast liquidproof outlet boxes.

Heaters with a built-in thermostat are normally furnished with a NEMA 1 rectangular sheet metal enclosure having combination 1/2″–3/4″ knockouts. However, those heaters drawing more than 40 amps are furnished with welded steel outlet boxes having 1″ or 1¼″ hubs for electrical connections.

Built-In Thermostats provide automatic temperature control without the necessity of installing a separate well for the thermostat bulb in the field and making electrical connections between the heater and control. The thermostats are fully adjustable from 0-100/120° F, 40-120° F, or 60-250° F.

Standard thermostats are single-pole for single-phase heaters and for pilot duty three phase applications and two pole for deenergizing load carrying applications, see page 48 for selection criteria.

The thermostat’s pilot duty rating is 250 VA at 277 volts maximum.

Element Spacers are made from Type 304 stainless steel to maintain a uniform distance between elements, thus preventing hot spots.

Epoxy Seals for a moisture resistant seal where fluid temperatures do not exceed 250° F.

UL and CSA Listings are available. All standard copper, Type 304 and 316 stainless steel and Incoloy sheathed heaters are listed by the Underwriters Laboratories under Reference E23541. These heaters, as well as steel sheathed heaters, are also available with the CSA (Canadian Standards Association) label under File No. LR11895. Some non-standard constructions can be UL and CSA labeled. Consult factory for availability.

Optional Features

Liquidproof NEMA 4 Outlet Box

(Without Built-In Thermostat)

Cast box with threaded, gasketed cover and 1″ NPT female threaded hubs for electrical connections. For applications where there is danger of moisture entering the outlet box.

Explosion Resistant Heater

Rated for Class I, Div. I, Groups B, C & D.

Liquidproof NEMA 4 Outlet Box (With Built-In Thermostat)

Welded steel outlet box with enamel finish and gasketed cover. Pilot light is visible through lens cover. Two 1″ NPT hubs provided for electrical connections. Stainless steel outlet box is available as an option.

Single-Pole, Single-Throw Thermostats

Standard on all singlephase heaters and all pilot duty applications. If pilot light or an ON/OFF switch is required, specify double-pole single-throw thermostat.

Omit Outlet Box

For applications where heater terminals will be protected by field-furnished enclosures.

Special Sheath Materials

Incoloy 800, Inconel 600, Type 316 stainless steel and Monel 400 available.

Special Header Materials

Incoloy 800, Inconel 600 and Type 316 stainless steel headers available.

Longer Elements

Consult factory for length and wattage limits per element.

UL/CSA Approval

Available on all standard heaters listed.

Longer Element Cold Ends

Cold ends are 3/4″ for copper, or 1-5/16″ for stainless and steel. In vertically mounted heaters and other applications where the liquid will not completely cover the elements, immersion length should be increased by the length of additional cold end.

8″ – 150#

| 48 Watts per sq. inch – Water & Mild Solutions | |||||

| Immersed Length “B” | Volts 3-Ph. | KW | No. Circ. | Cat. No. | Wt. (lbs.) |

| 27 ⅞” | 240 480 | 50 | 3 3 | 8H18-50-3 8H18-50-5 | 85 |

| 36 ⅞” | 240 480 | 75 | 6 3 | 8H18-75-3 8H18-75-5 | 94 |

| 43 ¾” | 240 480 | 100 | 6 3 | 8H18-100-3 8H18-100-5 | 100 |

| 51 ⅞” | 240 480 | 120 | 6 3 | 8H18-120-3 8H18-120-5 | 110 |

| 61 ⅜” | 240 480 | 150 | 6 6 | 8H18-150-3 8H18-150-5 | 118 |

| 69 ⅞” | 240 480 | 175 | 6 6 | 8H18-175-3 8H18-175-5 | 125 |

| 78 ⅞” | 240 480 | 200 | 6 6 | 8H18-200-3 8H18-200-5 | 135 |

| 22 Watts per sq. inch – Light wt. oils, caustics, air, & gases | |||||

| Immersed Length “B” | Volts 3-Ph. | KW | No. Circ. | Cat. No. | Wt. (lbs.) |

| 32 ⅞” | 240 480 | 30 | 2 1 | 8M18-30-3 8M18-30-5 | 90 |

| 43 ¾” | 240 480 | 40 | 3 1 | 8M18-40-3 8M18-40-5 | 100 |

| 51 ⅞” | 240 480 | 50 | 3 2 | 8M18-50-3 8M18-50-5 | 110 |

| 61 ⅜” | 240 480 | 60 | 3 2 | 8M18-60-3 8M18-60-5 | 118 |

| 69 ⅞” | 240 480 | 70 | 6 2 | 8M18-70-3 8M18-70-5 | 125 |

| 78 ⅞” | 240 480 | 80 | 6 2 | 8M18-80-3 8M18-80-5 | 135 |

| 13 Watts per sq. inch – Med. wt. oils, No. 4 & 5 fuel oil, corrosives, air & gases | |||||

| Immersed Length “B” | Volts 3-Ph. | KW | No. Circ. | Cat. No. | Wt. (lbs.) |

| 27 ⅞” | 240 480 | 12.5 | 1 1 | 8L18-12-3 8L18-12-5 | 85 |

| 36 ⅞” | 240 480 | 18.7 | 1 1 | 8L18-18-3 8L18-18-5 | 94 |

| 43 ¾” | 240 480 | 25 | 2 1 | 8L18-25-3 8L18-25-5 | 100 |

| 51 ⅞” | 240 480 | 30 | 2 1 | 8L18-30-3 8L18-30-5 | 110 |

| 61 ⅜” | 240 480 | 37.5 | 2 1 | 8L18-37-3 8L18-37-5 | 118 |

| 69 ⅞” | 240 480 | 44 | 3 1 | 8L18-44-3 8L18-44-5 | 125 |

| 78 ⅞” | 240 480 | 50 | 3 3 | 8L18-50-3 8L18-50-5 | 135 |

| 8 Watts per sq. inch – Heavy oils, #6 & Bunker C fuel oils, air & gases | |||||

| Immersed Length “B” | Volts 3-Ph. | KW | No. Circ. | Cat. No. | Wt. (lbs.) |

| 32 ⅞” | 240 480 | 10 | 1 1 | 8V18-10-3 8V18-10-5 | 90 |

| 43 ¾” | 240 480 | 13.3 | 1 1 | 8V18-13-3 8V18-13-5 | 100 |

| 51 ⅞” | 240 480 | 16.7 | 1 1 | 8V18-16-3 8V18-16-5 | 110 |

| 61 ⅜” | 240 480 | 20 | 1 1 | 8V18-20-3 8V18-20-5 | 118 |

| 69 ⅞” | 240 480 | 23.3 | 2 1 | 8V18-23-3 8V18-23-5 | 125 |

| 78 ⅞” | 240 480 | 26.7 | 2 1 | 8V18-26-3 8V18-26-5 | 135 |

10″ – 150#

| 48 Watts per sq. inch – Water & Mild Solutions | |||||

| Immersed Length “B” | Volts 3-Ph. | KW | No. Circ. | Cat. No. | Wt. (lbs.) |

| 27 ⅞” | 240 480 | 75 | 3 3 | 10H27-75-3 10H27-75-5 | 132 |

| 36 ⅞” | 240 480 | 112 | 3 3 | 10H27-112-3 10H27-112-5 | 143 |

| 43 ¾” | 240 480 | 150 | 9 3 | 10H27-150-3 10H27-150-5 | 152 |

| 51 ⅞” | 240 480 | 180 | 9 3 | 10H27-180-3 10H27-180-5 | 163 |

| 61 ⅜” | 240 480 | 225 | 9 3 | 10H27-225-3 10H27-225-5 | 175 |

| 69 ⅞” | 240 480 | 260 | 9 9 | 10H27-260-3 10H27-260-5 | 188 |

| 78 ⅞” | 240 480 | 300 | 9 9 | 10H27-300-3 10H27-300-5 | 200 |

| 22 Watts per sq. inch – Light wt. oils, caustics, air, & gases | |||||

| Immersed Length “B” | Volts 3-Ph. | KW | No. Circ. | Cat. No. | Wt. (lbs.) |

| 32 ⅞” | 240 480 | 45 | 3 3 | 10M27-45-3 10M27-45-5 | 140 |

| 43 ¾” | 240 480 | 60 | 3 3 | 10M27-60-3 10M27-60-5 | 152 |

| 51 ⅞” | 240 480 | 75 | 3 3 | 10M27-75-3 10M27-75-5 | 163 |

| 61 ⅜” | 240 480 | 90 | 3 3 | 10M27-90-3 10M27-90-5 | 175 |

| 69 ⅞” | 240 480 | 105 | 3 3 | 10M27-105-3 10M27-105-5 | 188 |

| 78 ⅞” | 240 480 | 120 | 3 3 | 10M27-120-3 10M27-120-5 | 200 |

| 13 Watts per sq. inch – Med. wt. oils, No. 4 & 5 fuel oil, corrosives, air & gases | |||||

| Immersed Length “B” | Volts 3-Ph. | KW | No. Circ. | Cat. No. | Wt. (lbs.) |

| 27 ⅞” | 240 480 | 18.7 | 1 1 | 10L27-18-3 10L27-18-5 | 132 |

| 36 ⅞” | 240 480 | 28 | 3 1 | 10L27-28-3 10L27-28-5 | 143 |

| 43 ¾” | 240 480 | 37.5 | 3 1 | 10L27-37-3 10L27-37-5 | 152 |

| 51 ⅞” | 240 480 | 45 | 3 3 | 10L27-45-3 10L27-45-5 | 163 |

| 61 ⅜” | 240 480 | 56 | 3 3 | 10L27-56-3 10L27-56-5 | 175 |

| 69 ⅞” | 240 480 | 65 | 3 3 | 10L27-65-3 10L27-65-5 | 188 |

| 78 ⅞” | 240 480 | 75 | 3 3 | 10L27-75-3 10L27-75-5 | 200 |

| 8 Watts per sq. inch – Heavy oils, #6 & Bunker C fuel oils, air & gases | |||||

| Immersed Length “B” | Volts 3-Ph. | KW | No. Circ. | Cat. No. | Wt. (lbs.) |

| 32 ⅞” | 240 480 | 15 | 1 1 | 10V27-15-3 10V27-15-5 | 140 |

| 43 ¾” | 240 480 | 20 | 1 1 | 10V27-20-3 10V27-20-5 | 152 |

| 51 ⅞” | 240 480 | 25 | 1 1 | 10V27-25-3 10V27-25-5 | 163 |

| 61 ⅜” | 240 480 | 30 | 3 1 | 10V27-30-3 10V27-30-5 | 175 |

| 69 ⅞” | 240 480 | 35 | 3 1 | 10V27-35-3 10V27-35-5 | 188 |

| 78 ⅞” | 240 480 | 40 | 3 1 | 10V27-40-3 10V27-40-5 | 200 |