Hairpin Tubular

AccuTherm’s years of manufacturing and application experience has been combined to provide a high quality product, off the shelf, at low cost.

It is our goal to provide you, the customer, with the finest product available, engineered to do the desired job in your application, at the lowest cost. Our stock allows us to do this with minimum lead time.

Approvals

Standard Features

UL & CSA Recognition.

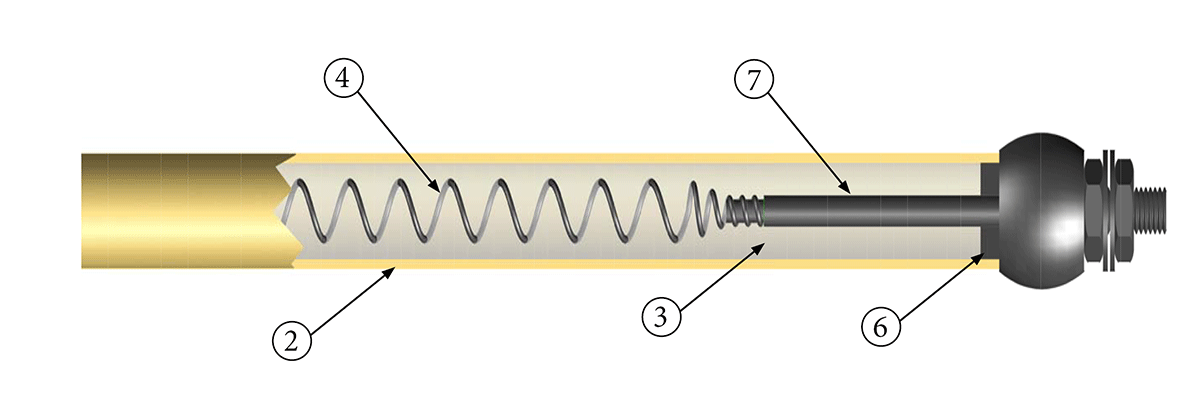

Incoloy 840 sheath standard on all items-allows for the widest coverage of applications and temperatures, plus gives a margin of safety should there by any unknown corrosives or contaminants in the application.

High purity MgO powder compacted to provide maximum heat conductivity and optimum dielectric strength.

Type ‘A’ 80/20 resistance wire sized to provide lowest wire watt density for maximum life.

Fusion welded junction between pinlresistance wire to provide a 360° circumferential joint, giving superior strength and life

Choice of end seals for a variety of applications. See item 2, adjacent column.

Integral cold pins centered in compacted MgO of nickel plated steel to provide optimum in current carrying capacity.

100% inspected for:

A. Dielectric or Hi-Pot between conductors and sheath.

B. Insulation resistance.

C. Wattage.

All stock Tubular Heaters are recognized components under U.L. file #E78533.

Optional Features

Mounting methods:

a.) Bulkhead fittings

b.) Brackets

c.) Flanges

End seals:

a.) Silicone resin for 300° F continuous maximum temperatures and the most economy.

b.) Epoxy for 266° F continuous maximum temperatures and high moisture areas.

c.) Vulcanized overmolded leads.

d.) Ceramic to metal end seals.

Formations to nearly every imaginable configuration–see link below.

Terminations-leadwires, plate terminals with screws, threaded stud.

Other sheath materials available; copper, steel, stainless, Monel 400, lnconel 600, Carpenter 20, Hastelloy and Titanium. Consult factory.

Special lengths, wattages and voltages.

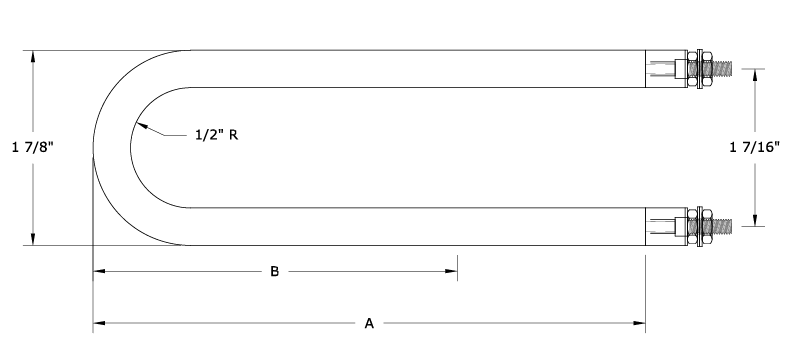

.430″ Sheath Diameter – 20-23 Watts/sq in.

|

SHEATH LENGTH “A”

|

HEATED LENGTH “B”

|

WATTS

|

VOLTS

|

CATALOG NUMBER

|

|

13 ½

|

10 ½

|

750

|

240 480

|

HP42-75-2 HP42-75-4

|

|

19 1⁄16

|

14 1⁄16

|

1000

|

240 480

|

HP42-100-2 HP42-100-4

|

|

21 ⅜

|

18 ⅜

|

1250

|

240 480

|

HP42-125-2 HP42-125-4

|

|

26 ¼

|

21 ¼

|

1500

|

240 480

|

HP42-150-2 HP42-150-4

|

|

34 ¼

|

29 ¼

|

2000

|

240 480

|

HP42-200-2 HP42-200-4

|

|

41 ¾

|

36 ¾

|

2500

|

240 480

|

HP42-250-2 HP42-250-4

|

|

49

|

44

|

3000

|

240 480

|

HP42-300-2 HP42-300-4

|

|

53

|

48

|

3333

|

240 480

|

HP42-333-2 HP42-333-4

|

|

66

|

61

|

4167

|

240 480

|

HP42-416-2 HP42-416-4

|

|

79

|

74

|

5000

|

240 480

|

HP42-500-2 HP42-500-4

|

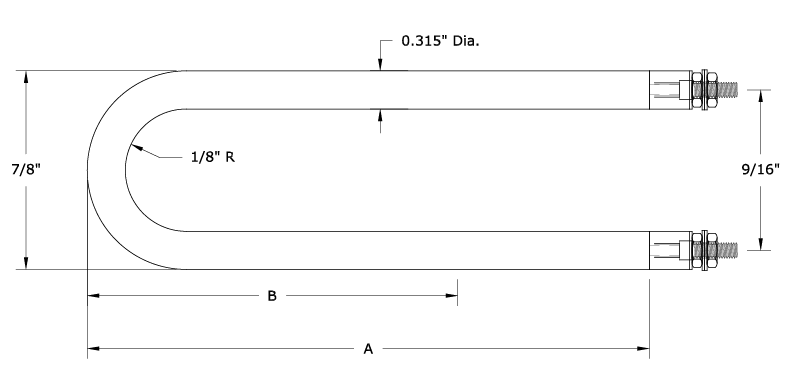

.315″ Sheath Diameter – 20-23 Watts/sq in.

|

SHEATH

LENGTH “A” |

HEATED

LENGTH “B” |

WATTS

|

VOLTS

|

CATALOG

NUMBER |

|

7 ⅝

|

4 ⅞

|

250

|

120

240 |

HP32-25-1

HP32-25-2 |

|

10 ⅝

|

7 ⅞

|

375

|

120

240 |

HP32-37-1

HP32-37-2 |

|

13 ⅝

|

10 ⅞

|

500

|

120

240 |

HP32-50-1

HP32-50-2 |

|

21 ⅛

|

18 ⅜

|

750

|

120

240 |

HP32-75-1

HP32-75-2 |

|

27 ¾

|

25

|

1000

|

120

240 |

HP32-100-1

HP32-100-2 |

|

40 ¼

|

37 ½

|

1500

|

120

240 |

HP32-150-1

HP32-150-2 |