Terminal Assembly Options

Terminal Assembly – Ceramic, Lead Wire, Rubber, Screw Lug and Threaded Stud

Except as noted, various terminations, insulators and seals can be combined as required to fit the application.

Standard Features

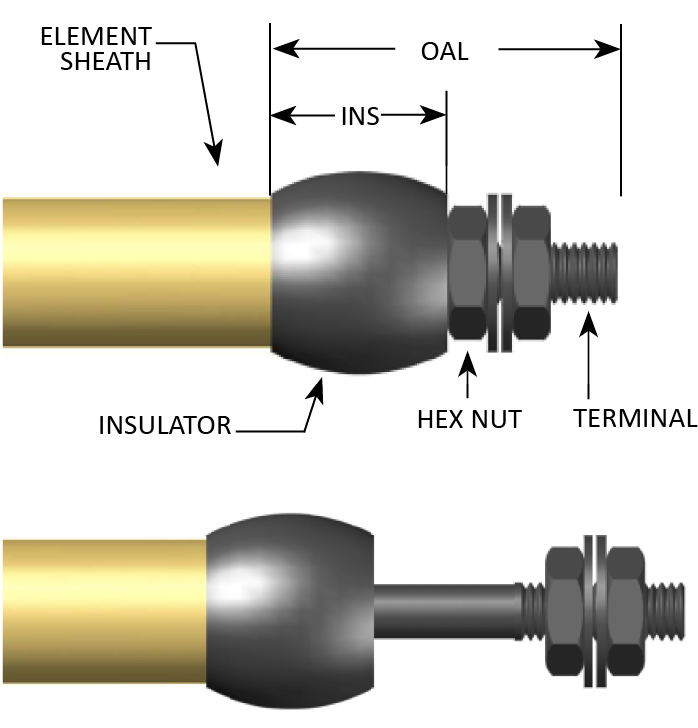

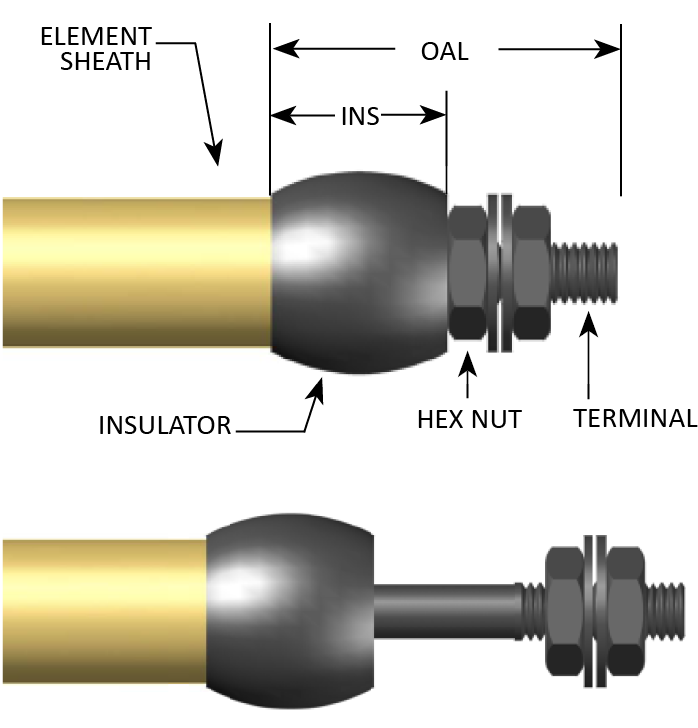

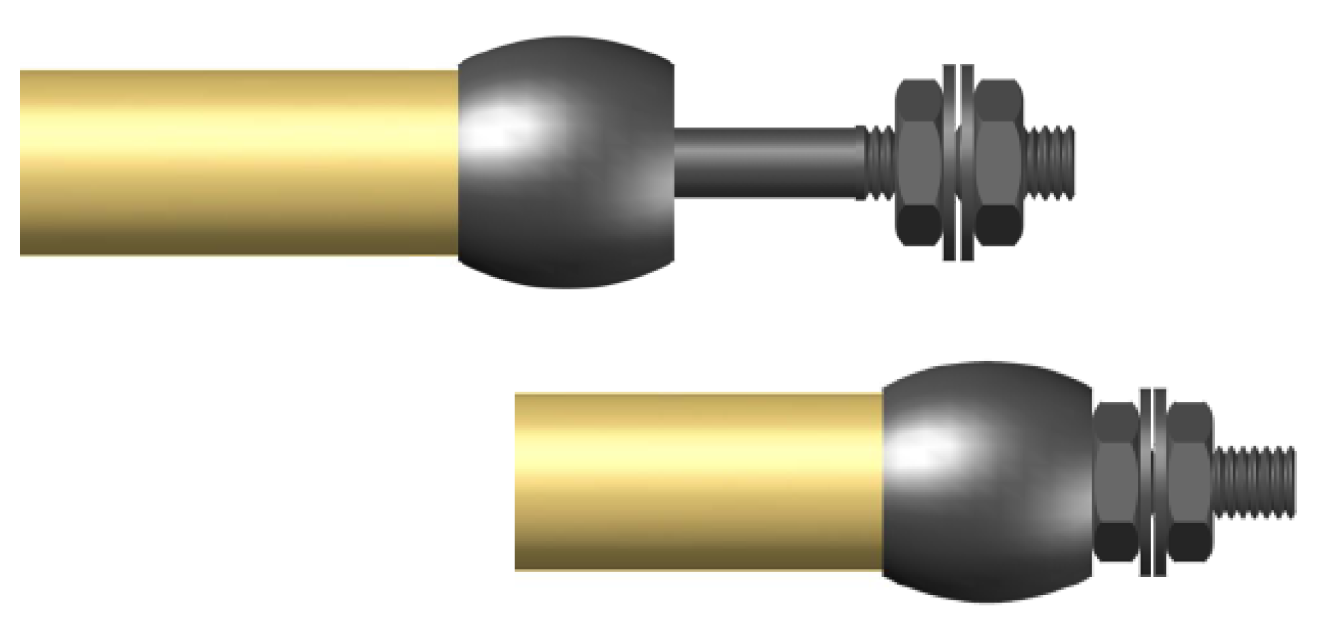

Threaded Terminal (standard)

Description:

Stainless steel stud with threaded length

Optional:

Insulators available in silicone rubber (std) or optional mica or ceramic where available

Use:

For lead attachment in the field.

600V rating

| Thread Sizes* | OAL Standard | INS Standard (Insulator Dim) |

| 6-32 | 1” | 0.50” |

| 8-32 | ||

| 10-32 | ||

| 1/4-20 |

* 6-32 thread is standard for .250 and .260

Element Diameters, 10-32 thread is standard for all other Diameters.

Other thread size, INS and OAL lengths available upon request.

Standard Features

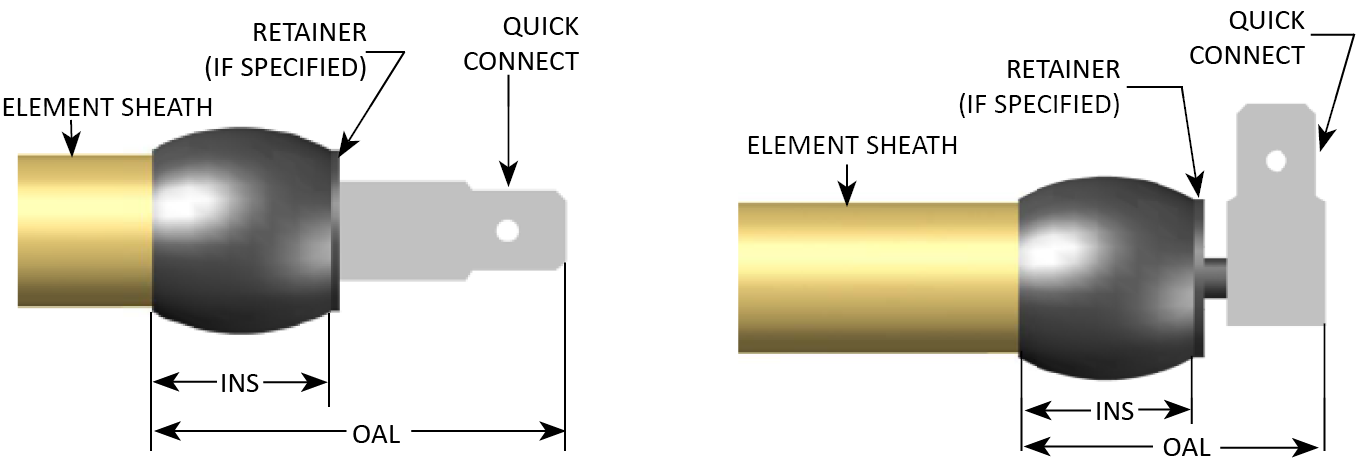

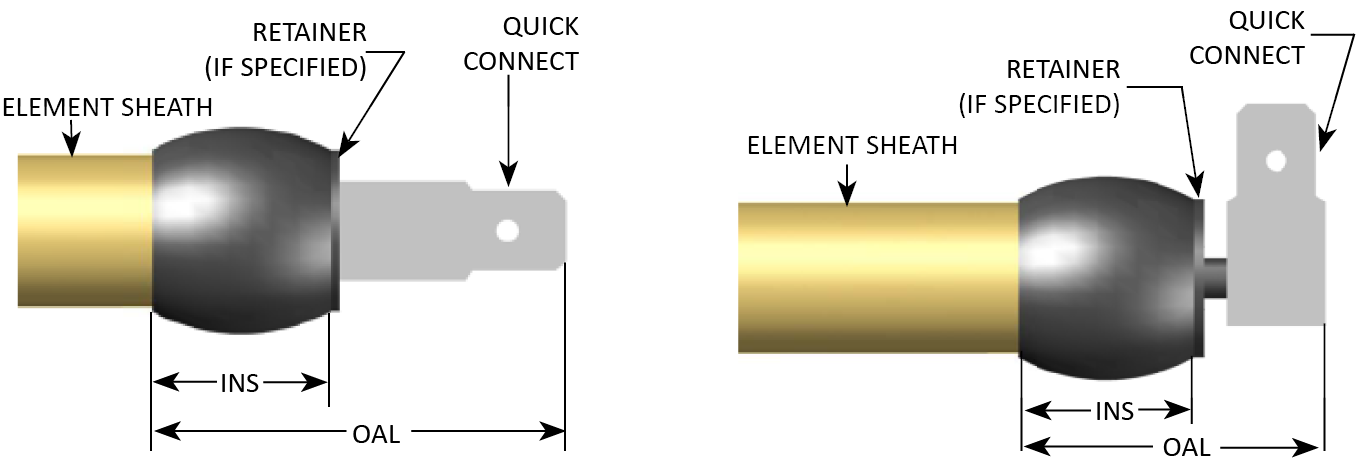

Quick Connect Terminal

Description:

Standard 1/4” plated steel quick connect configuration

Optional:

Insulators available in silicone rubber (std) or optional mica or ceramic where available

Use:

For connection to matching female terminal on field funished lead. 30 amp max, see table for voltage rating

| Voltage Range |

OAL Standard (Straight terminal) |

OAL Standard (90 Deg terminal) |

INS Standard (Insulator Dim) |

| 0-250V | 0.75” | 0.813” | 0.25 |

| 251-600V | 1” | 1.063” | 0.5 |

Standard Features

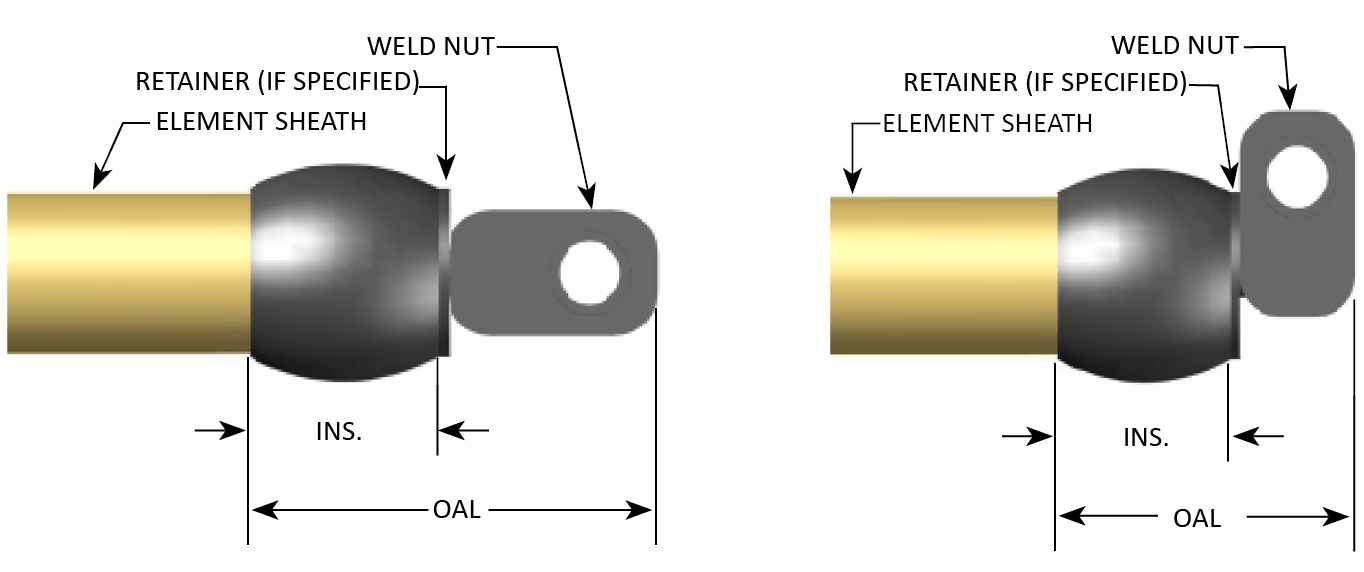

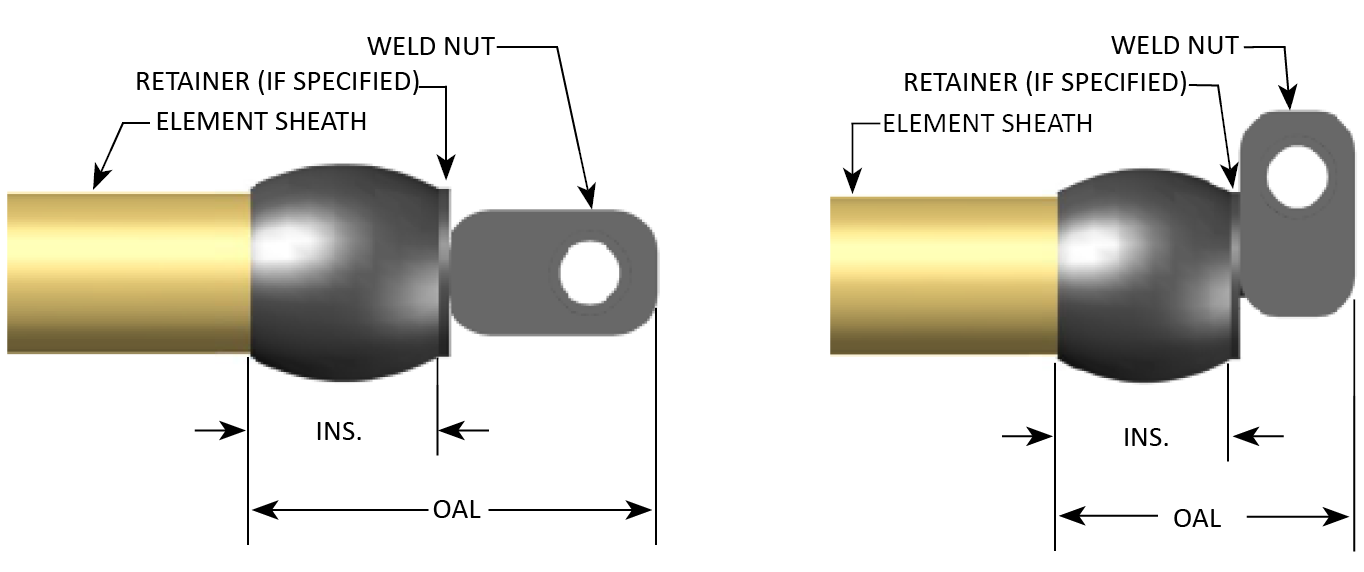

Weld Nut

Description:

Tab with internal thread is welded to

terminal pin and furnished with terminal

screw

Use:

Where it is more convenient to use this

terminal orientation.

| Voltage Range |

OAL Standard (Straight terminal) |

OAL Standard (90 Deg terminal) |

INS Standard (Insulator Dim) |

| 0-250V | 0.813” | 0.563” | 0.25 |

| 251-600V | 1.063” | 0.813” | 0.5 |

Standard Features

Neoprene Insulated Leads

Description:

Standard Bare Copper or Tin Plated Copper Conductors insulated with Neoprene. 90oC Neoprene insulation with thickness of 5/64” or 1/16”.

Use:

Used primarily for internal wiring or wiring of defrost and refrigeration applications up to 600V. See Neoprene and Expoxy filled Terminal #5 for applications that require protection for wet (immersed) refrigeration type applications.

Neoprene exhibits supreme abrasion, cut-through oil, and solvent resistance. Neoprene is also known for its long service life and wide ranges of temperature and usability. It is remarkably flame retardant and self-extinguishing. (Military products often incorporate Neoprene.)

PVC Insulated Leads

Description:

Standard Bare Copper or Tin Plated Copper Conductors insulated with PVC. 105oC PVC insulation with thickness of 1/32”.

Use:

Used primarily for internal wiring of appliances up to 600V or with thickness of 1/16” for internal wiring of refrigeration equipment. See Valox Terminal #5 for applications that require protection for moist refrigeration type applications.

PVC is relatively inexpensive, with the potential to be used in diverse applications. It is flame, moisture, and abrasion resistant. It also holds up against gasoline, ozone, acids, and solvents. PVC should not be used when flexibility and an extended flex life are required at low temperatures.

Silicone Insulated Leads with Glass Braid (SRG)

Description:

Stranded Tin Plated Copper Conductors insulated with Silicone Rubber and Glass Braid. 200oC Silicone Rubber insulation with thickness of 1/32”.

Use:

Used primarily for internal wiring of applicances up to 600V. SRG is the standard suppied insulation material, with the exception of defrost and refrigeration applications.

Type TGGT Leads

Description:

Stranded Nickel-Clad Copper Conductors insulated with PTFE tapes and Glass Braid. 250oC PTFE tapes with thickness of 1/64” covered by wrapped fiberglass yarns and a treated glass braid jacket.

Use:

Used where the leadwire is exposed to high temperatures such as in industrial processing up to 600V.

Mica Insulated Leads with Glass Braid (MGT)

Description:

Stranded Nickel-Clad Copper Conductors insulated with Mica Glass Tapes and Glass Braid. 450oC Glass reinforced Mica tapes with thickness of 1/32” and a treated glass braid jacket.

Use:

Used where the leadwire is exposed to extremely high temperatures up to 600V.

| Standard Supplied Wire Gauge | Limit Amps |

| 18 | 10 |

| 16 | 15 |

| 14 | 20 |

| 12 | 30 |

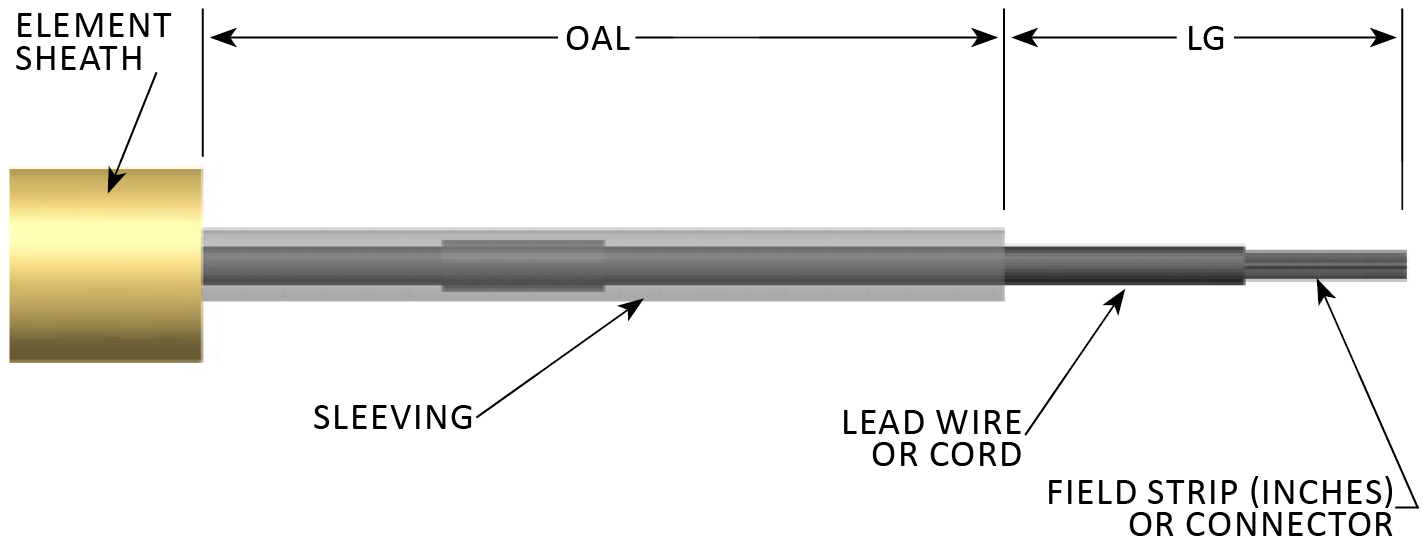

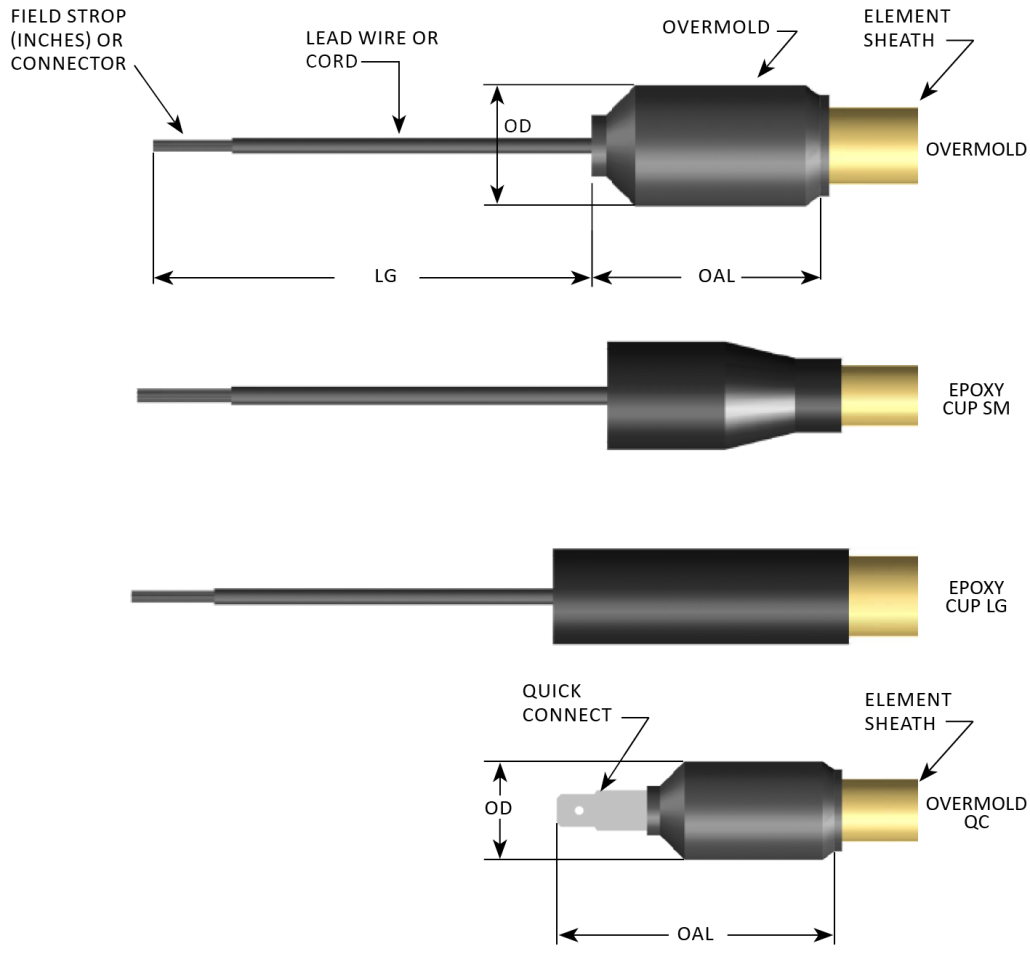

Standard Features

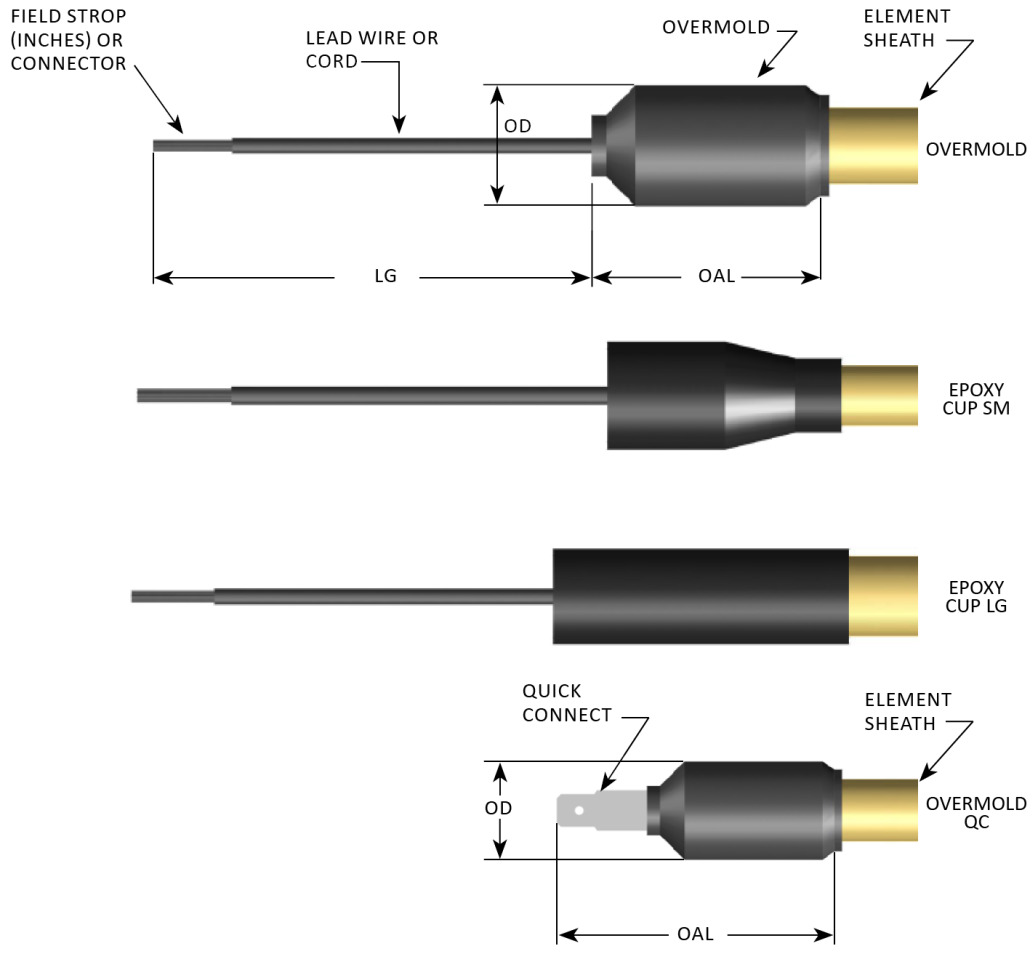

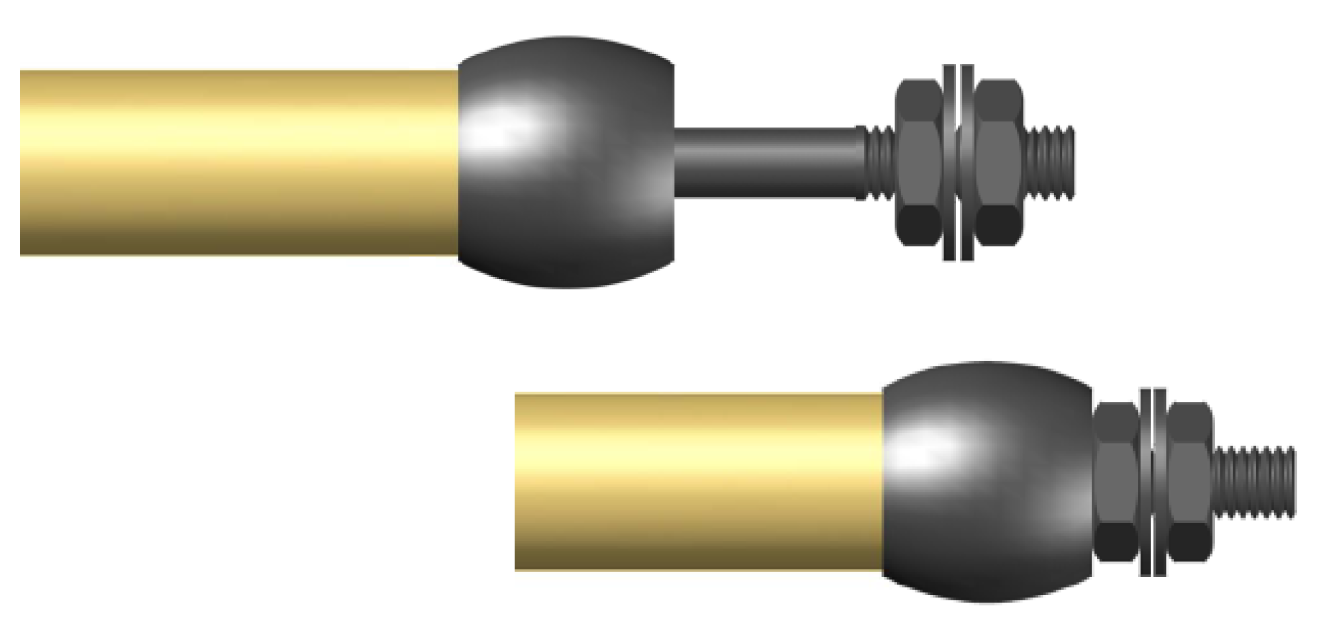

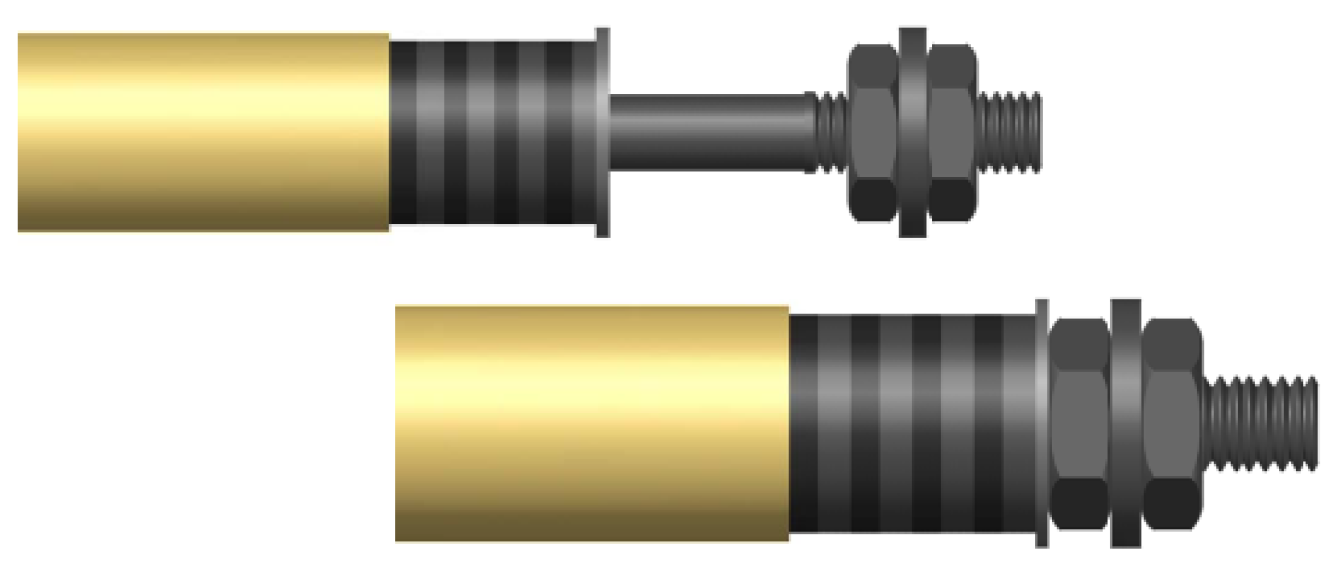

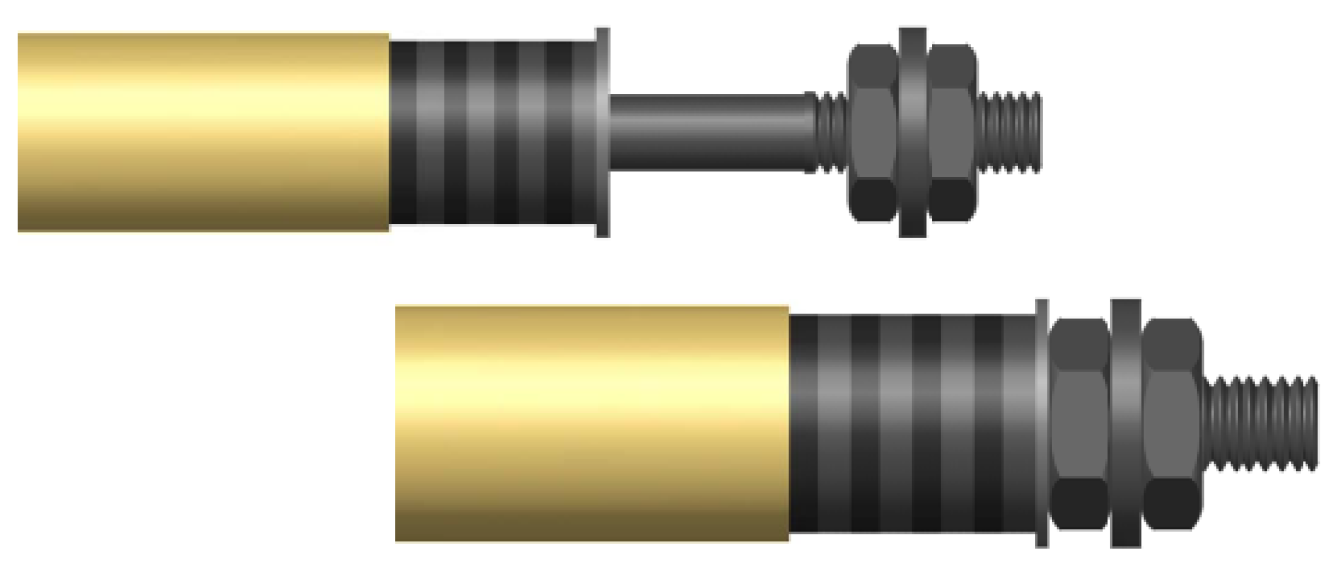

Defrost Terminal

Description:

Neoprene or Valox, Injection Molded overmold terminal

OR

Epoxy Filled Metal Cup Terminal

Description:

Epoxy resin fills a metallic adapter enclosing the connection between lead wire and element cold pin.

Use:

Primarily defrost applications and others where water may drop on the terminal end. UL Recognized under File SA3254.

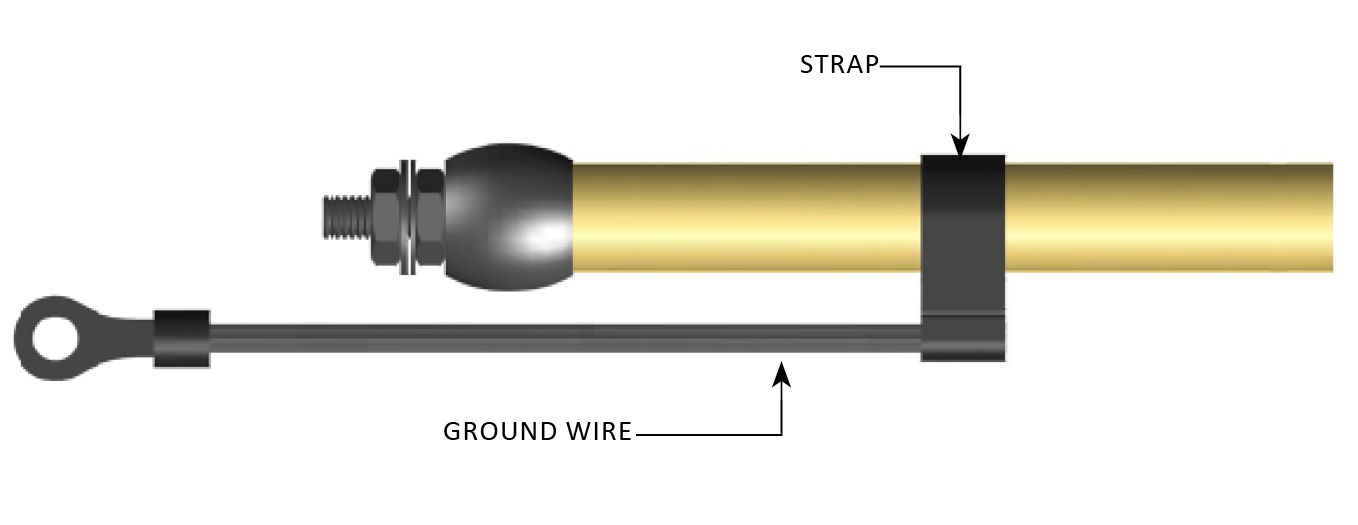

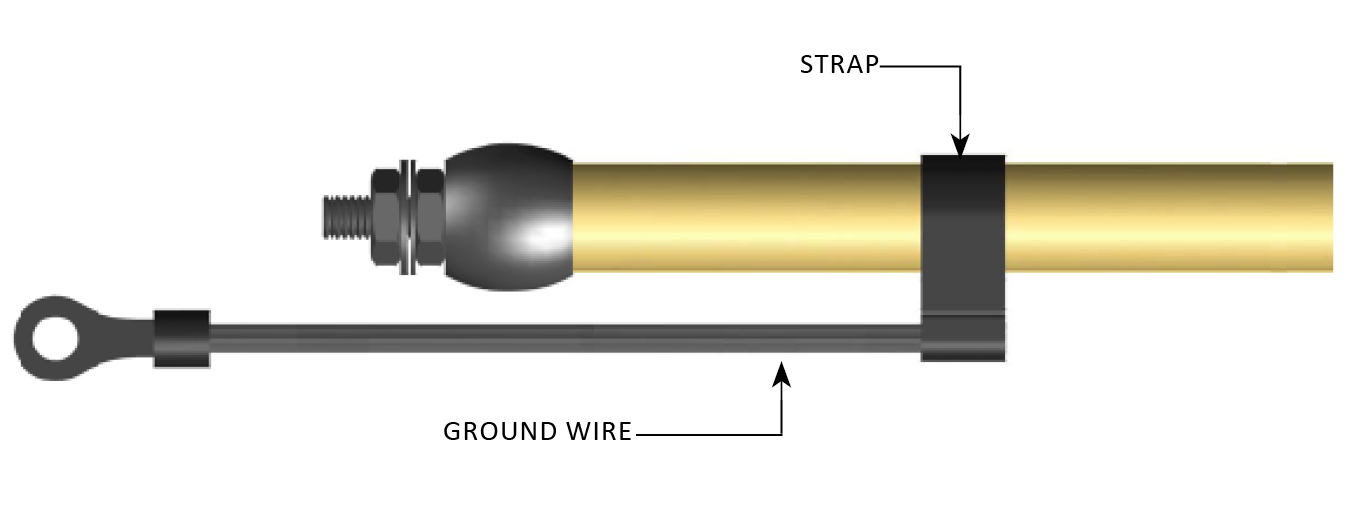

Grounding Strap (Optional)

Description:

To ground long straight single-pass finned tubular elements, eliminating arcing due to secondary currents.

Use:

Recommended for straight single-pass finned tubular elements over on expansion end. Verify adequate expansion clearances.

| Type | Material | Type | Element Sizes | OD | OAL | Location | Description |

| Overmold QC | Neoprene | One-Pass | 0.250 – 0.315 | 0.4375 | 1.0625 | Moist | T Series |

| Epoxy Cup SM | Epoxy/Metal | One-Pass | 0.315 | 0.5625 | 1.25 | Wet | Blank Series |

| Epoxy Cup LG | Epoxy/Metal | One-Pass | 0.475 | 0.5625 | 1.75 | Wet | Blank Series |

| Overmold | Neoprene | One-Pass | 0.250 – 0.375 | 0.4375 | 1.75 | Wet | W Series |

| Overmold | Neoprene | One-Pass | 0.430 – 0.490 | 0.75 | 1.75 | Wet | W Series* |

| Overmold | Valox | One-Pass | 0.250 – 0.315 | 0.4375 | 1.75 | Moist | J39 Series |

| Overmold | Valox | One-Pass | 0.375 – 0.430 | 0.5625 | 1.75 | Moist | J39 Series |

| Overmold | Valox | One-Pass | 0.475 | 0.75 | 1.5 | — | —* |

| Epoxy Cup LG | Epoxy/Metal | Two-Pass | 0.475 | 0.5625 | 1.75 | — | —* |

| Overmold | Neoprene | Two-Pass | 0.430 – 0.490 | 0.75 | 1.5 | Moist | X Series |

| * May be recognized under E78533 | |||||||

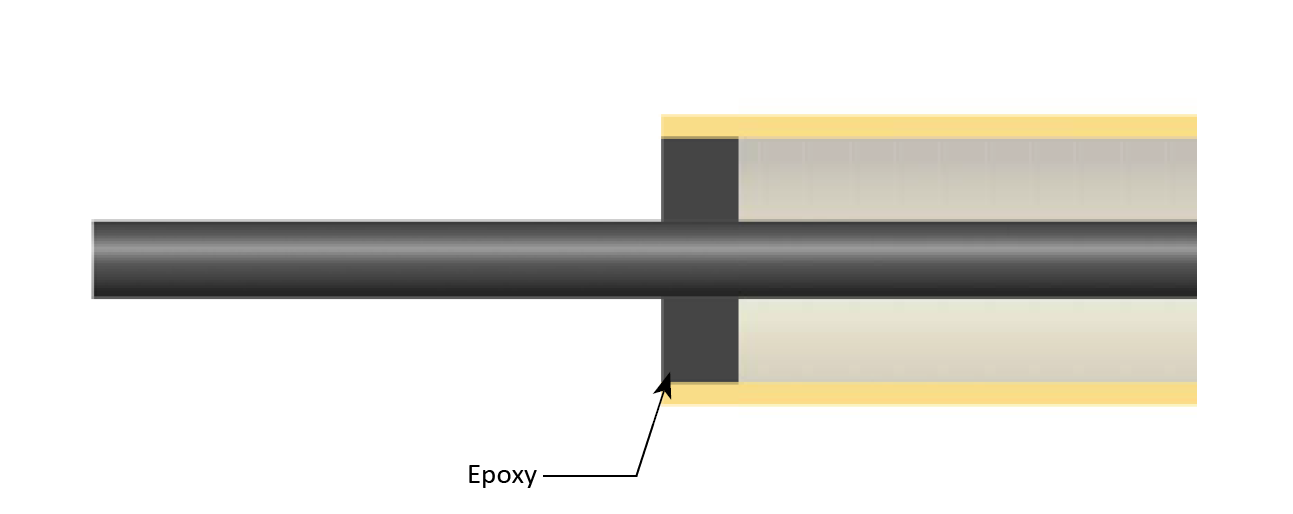

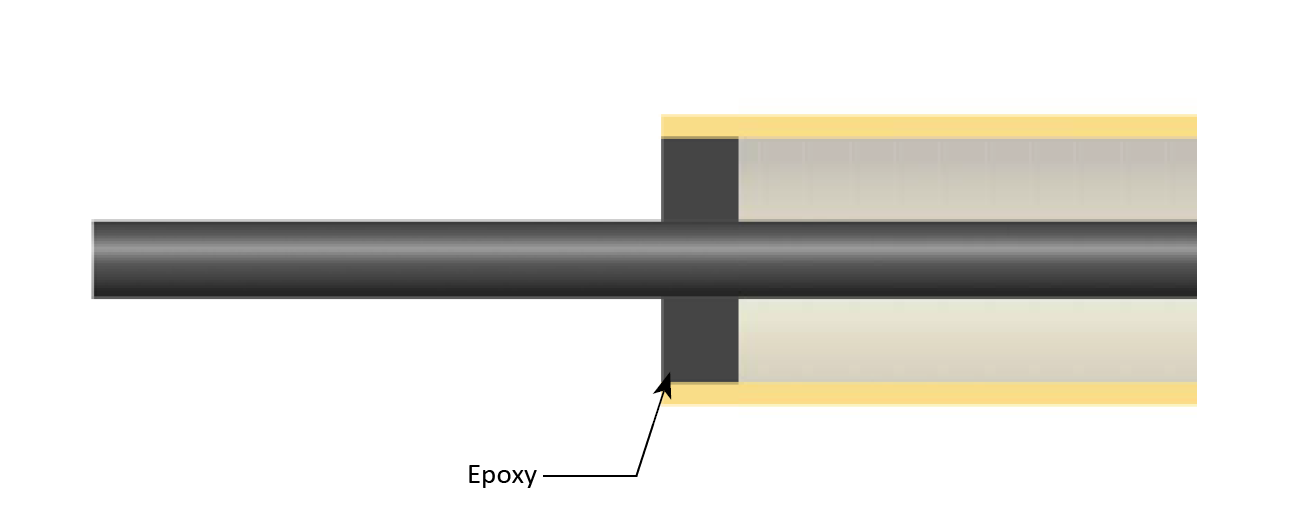

End Seal #1

Epoxy Barrier

Description:

Epoxy resin fills a 1/4” cavity above the magnesium oxide insulation, to form a barrier against moisture.

Use:

For applications where low to moderate humidity may be present in the terminal area. For use at 266oF maximum for 0.315 element and above. 194oF maximum for 0.260 elements and below.

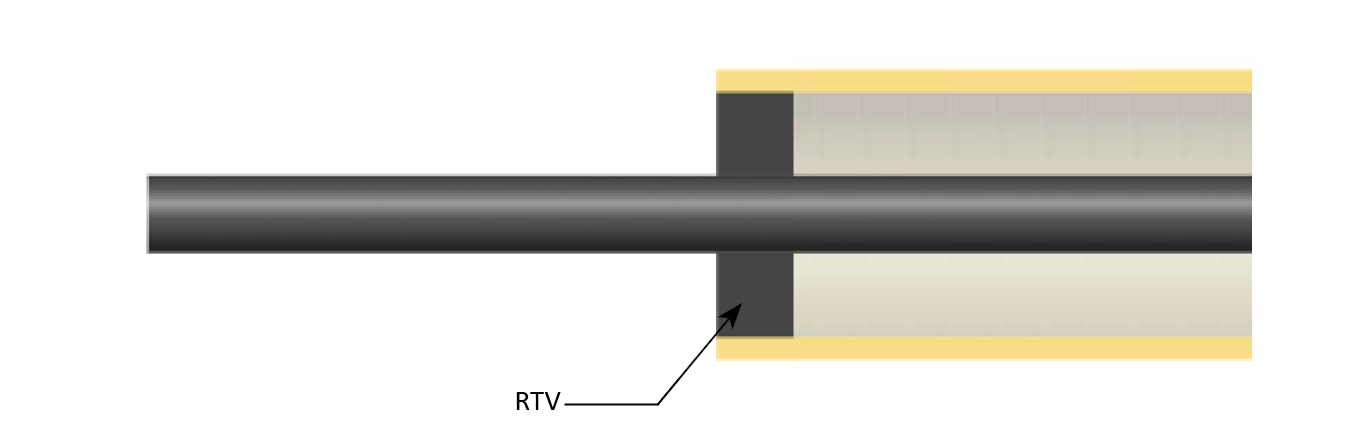

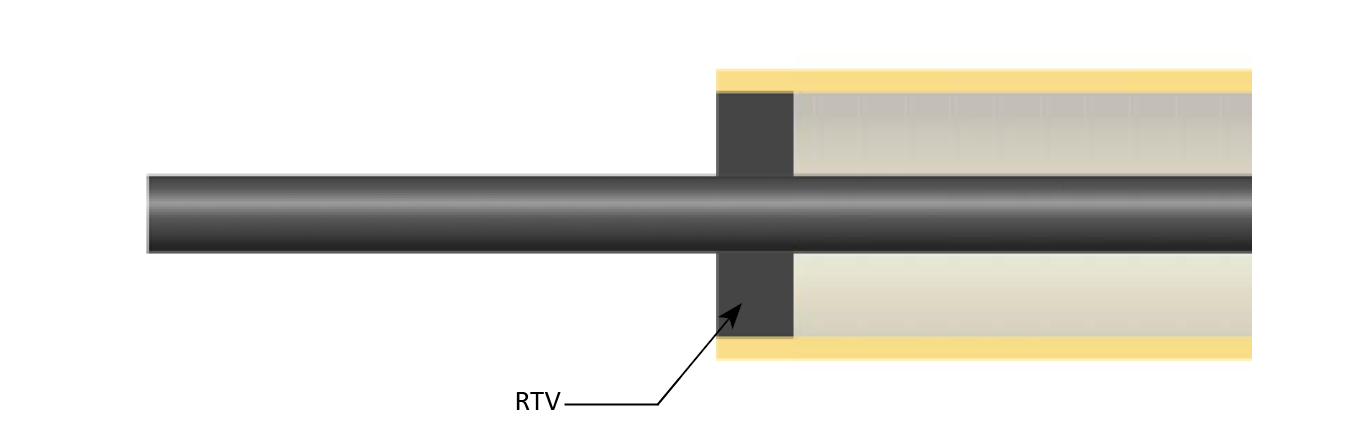

End Seal #2

RTV Barrier

Description:

RTV sealant forms a barrier against moisture.

Use:

For high temperature applications where temperatures may range up to 392oF or 428oF.

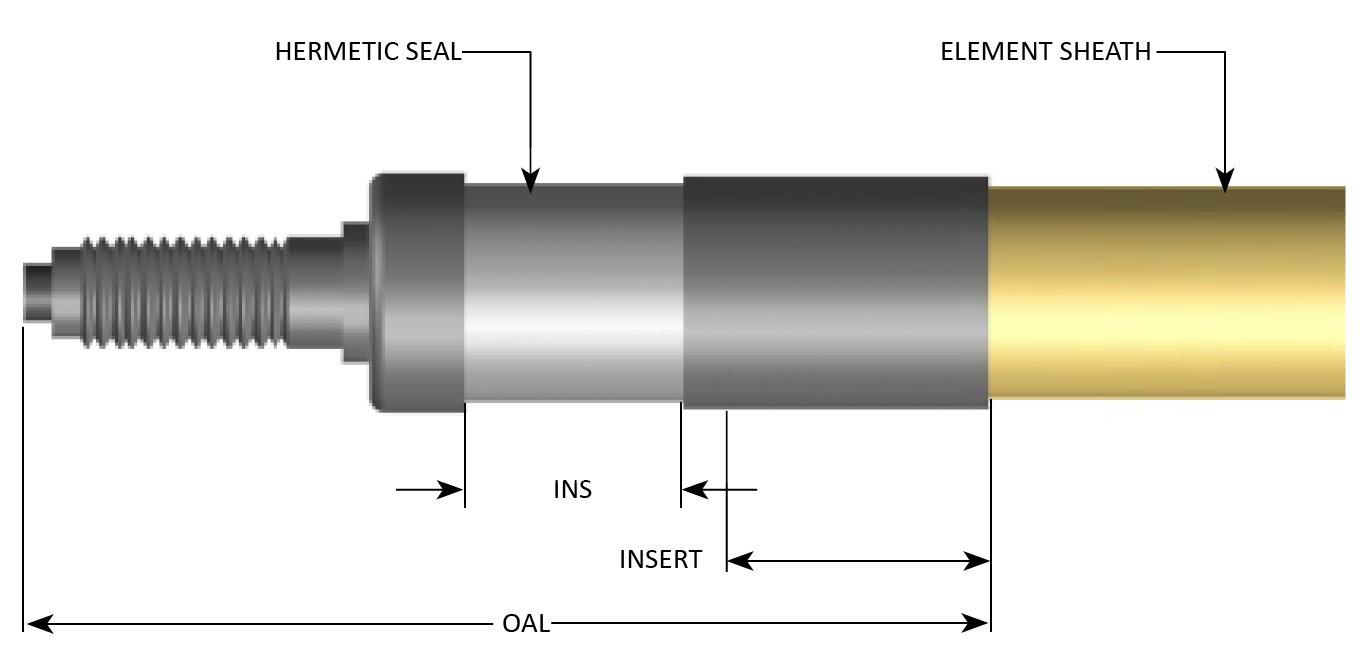

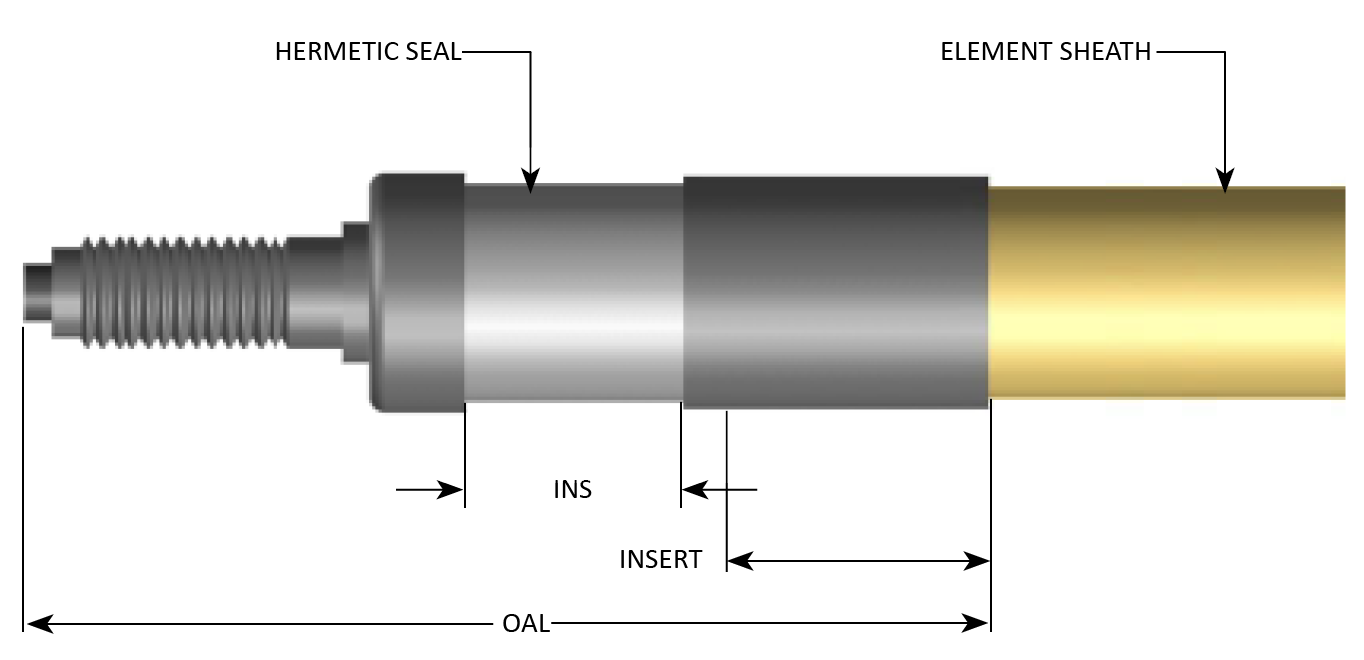

End Seal #3

Hermetic Seal

Description:

Ceramic to metal hermetic seal is soldered to the element sheath and cold pin.

Use:

Absolute moisture seal up to 1000oF.

Element Sheath:

Available in element diameters .430 and .475, consult factory for other availability.

| Element Sheath Diameter | INS Standard (Integral Ceramic Insulator Dim) | OAL Standard |

| 0.430 | 0.5 | 2.125” |

| 0.475 | 0.5 | 2.125” |

| Alternate element sheath diameters available upon request. | ||

Insulator #1

Silicone Rubber (standard)

Description:

General applications where terminal temperatures do not exceed 400oF. 1/4” thick insulation furnished up to 250V; 1/2” thick up to 600V. (Standard insulator unless otherwise specified)

Insulator #2

Mica

Description:

Applications where terminal temperatures do not exceed 900oF. 1/4” thick insulation furnished up to 250V; 1/2” thick up to 600V.

Insulator #3

Ceramic

Description:

Applications where terminal temperatures do not exceed 1400oF. 1/4” thick insulation furnished up to 250V; 1/2” thick up to 600V.